Posters

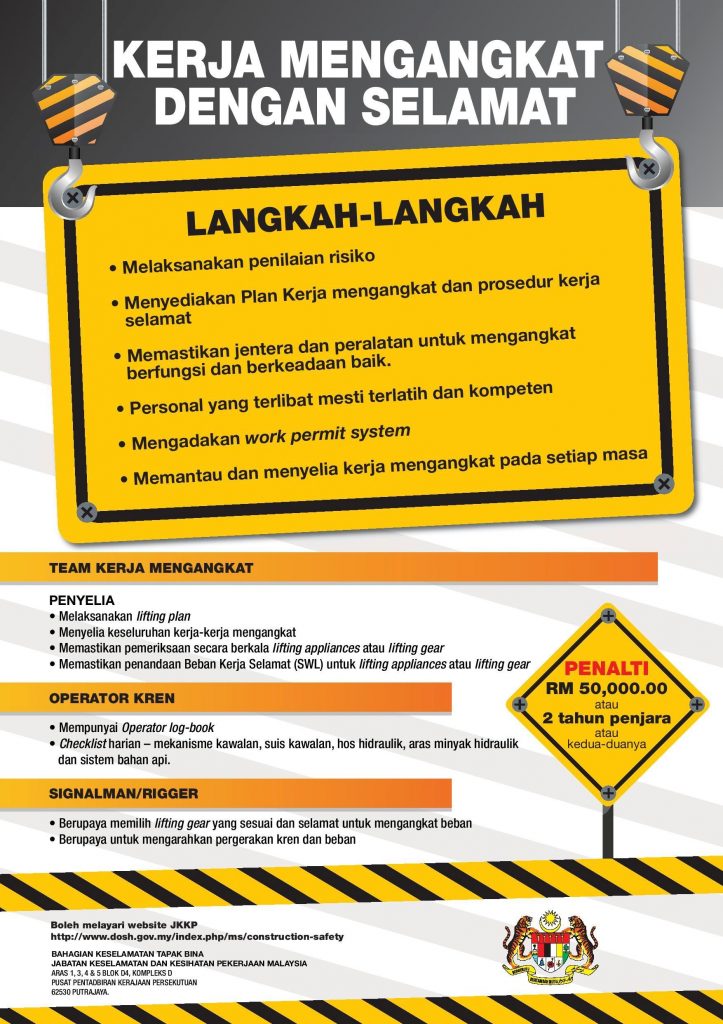

Safe Lifting Work

Steps:

- Conduct a risk assessment.

- Prepare Lifting Plans and safe work procedures.

- Ensure machinery and tools or equipment for lifting are functional and in good condition.

- Appoint trained and competent personnel.

- Establish a work permit system.

- Monitor and supervise lifting work at all times.

Lifting Working Group

- Supervisor

- Implementing a Lifting Plan.

- Supervise all lifting work.

- Ensure regular inspections of lifting tools and equipment.

- Ensure Safe Working Load marking for lifting tools or equipment.

- Crane Operator

- Prepared and updated operator logbook.

- Prepared and updated daily checklists for components such as control mechanisms, control switches, hydraulic hoses and hydraulic oil levels.

- Signalman/Ranger

- Be able to choose appropriate and safe lifting equipment.

- Able to direct the movement of cranes and loads.

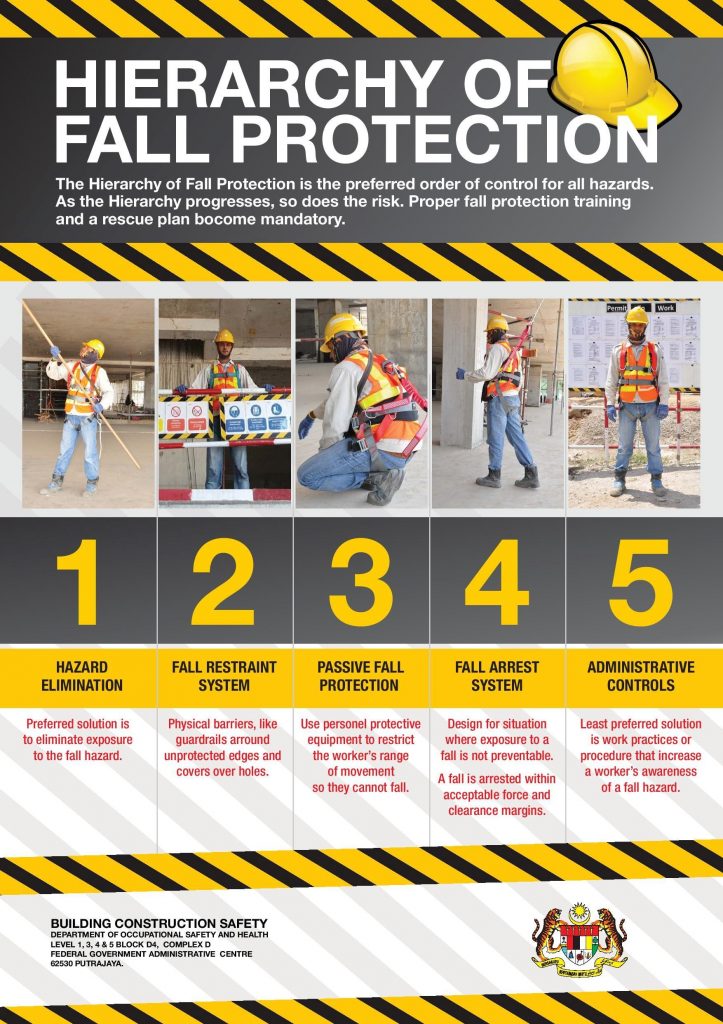

Fall Protection Hierarchy

The fall protection hierarchy is the best control sequence for all hazards. As the hierarchy changes, so do the risks. Proper fall protection training and rescue plans are essential.

- Hazard Elimination

- The best solution option is to eliminate exposure to the fall hazard.

- Fall Restraint System

- Physical barriers, such as guard rails around open edges and covers for holes (in the floor).

- Passive Fall Protection

- Use personal protective equipment to restrict workers' range of motion so they cannot fall.

- Fall Arrest System

- Designed for situations where exposure to falls cannot be eliminated. Falls are arrested at appropriate force and clearance distance.

- Administrative Control

- A less encouraged solution option is through work practices and procedures to increase employee awareness of fall hazards.

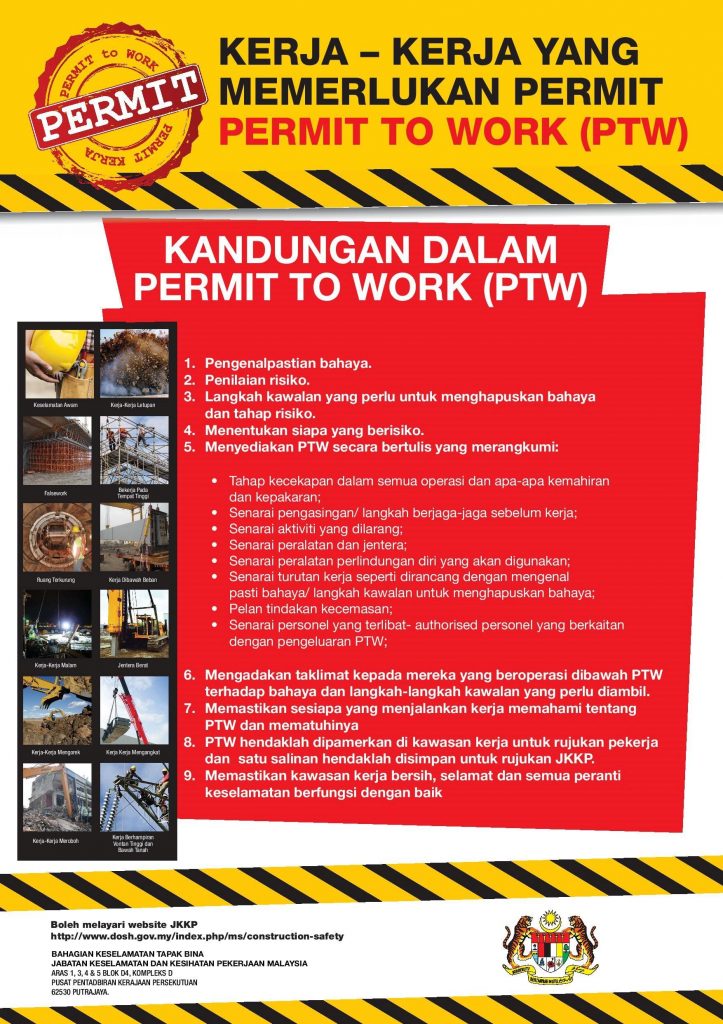

Works that require a Permit to Work (PTW)

- Public safety.

- Blasting work.

- Buffer work.

- Working at heights.

- Work in confined spaces.

- Work under load.

- Night work.

- Work using heavy machinery.

- Excavation work.

- Lifting work.

- Demolition work.

- Working near high voltage power lines.

PTW content

- Hazard identification.

- Risk assessment.

- Control measures necessary to eliminate hazards where practical, assess unavoidable risks and state appropriate measures that control risks at source.

- Determine who is at risk.

- Provide written PTW which includes:

- Level of competence in all operations and any skills and expertise;

- List of isolation/precautionary measures before work;

- List of prohibited activities;

- List of equipment and machinery;

- List of personal protective equipment to be used;

- Work sequence;

- Emergency action plan; and

- List of personnel involved.

- Conduct briefings for workers operating under PTW regarding hazards and control measures.

- Ensure employees understand and comply with PTW.

- The PTW must be displayed in the work area for employee reference.

- Ensures work areas are clean and safe, and all safety devices are functioning properly.

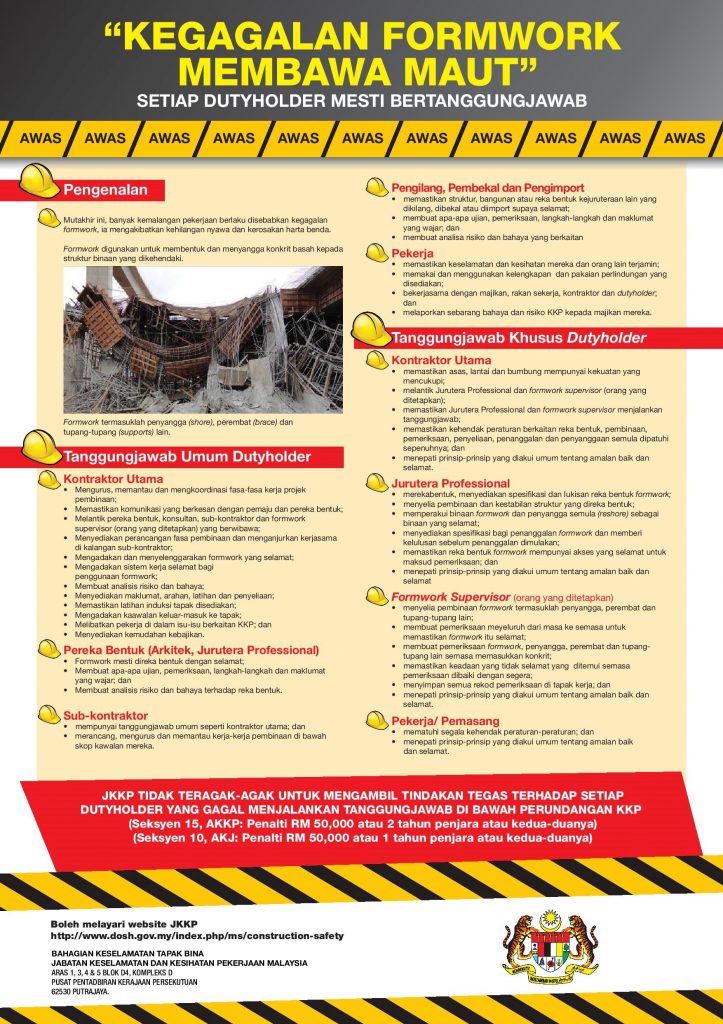

The failure of the formwork-support is fatal; every duty-bearer must be held accountable.

Introduction

Formwork and falsework are used to shape and support wet concrete into required structure. Formwork and falsework are used to shape and support wet concrete into required structure.

General responsibilities of duty bearers

- Principal Builder

- manage, monitor and coordinate the construction phase;

- ensuring effective communication with clients and designers;

- appoint competent designers, consultants, builders and supervisors (designated persons);

- prepare construction phase planning and organize cooperation among builders and coordinate their work;

- provide and maintain safe molds and supports;

- establish a safe work system for the use of molds and supports;

- providing information, instruction, training and supervision;

- provide site induction training;

- conducting access control to the site;

- involving employees in OSH-related issues; and

- provide welfare facilities.

- Designer (Architect, Professional Engineer)

- Ensure structural design is safe;

- make any tests, inspections and measures to identify, eliminate or control risks; and

- provide information to other duty holders.

- Builder

- have general responsibilities such as principal builders; and

- plan, manage and monitor construction works under its scope of control.

- Manufacturer, supplier and importer Manufacturer, supplier and importer

- ensuring that structures manufactured, supplied or imported are safe;

- make any tests, inspections, measures to identify, eliminate or control risks; and

- provide information to other duty holders.

- Employee

- ensure the safety and health of themselves and others who may be affected by their work;

- wear and use protective equipment and clothing provided by the employer;

- cooperate with his employer and other duty bearers; and

- report any hazards and risks to their employer.

Specific responsibilities of duty bearers

- Main Builder

- ensure that the foundation, floor and roof have sufficient strength;

- ensure that regulatory requirements relating to design, construction, inspection, supervision, removal and re-supporting are fully complied with; and

- comply with generally accepted principles of good and safe practice.

- Designer (Architect, Professional Engineer)

- designing and preparing specifications and design drawings for formwork-supports;

- supervise the construction and ensure the stability of the designed structure;

- certify that the mold and re-support are safe;

- prepare specifications for mold removal and provide approval before removal commences;

- ensuring that the mold design has safe access for inspection purposes; and

- comply with generally accepted principles of good and safe practice.

- Mold-Bearing Supervisor

- supervising the construction of formwork including supports, braces and other supports;

- conduct thorough inspections from time to time;

- inspecting formwork, supports, braces and other supports when pouring concrete;

- ensuring that any unsafe conditions found during inspections are repaired immediately;

- keep all inspection records; and

- comply with generally accepted principles of good and safe practice.

- Worker/Installer

- ensure that the construction and installation methods are safe when used; and

- comply with generally accepted principles of good and safe practice.